ELEKTROHIDRAULIESE SERVO CNC-PERSREM

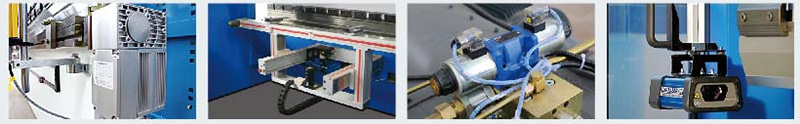

Standaardkonfigurasie

Y1 en Y2 sinchroniseer die persrem

Verstelbare vingerstop en voorsteun

X-as agtermeter deur servomotor met akkuraatheid +0.1mm

Japan vinnige klem vir topstoots

DELEM DA66T 3D grafiese operateurbeheer

Hidrouliese of meganiese kroning opsioneel

Duitsland Bosch Rexroth geslote lus elektrohidrouliese stelsel

CE-veiligheidssertifisering

DA52S

●8" breëband kleurskerm,

● Maksimum 4-as beheer (Y1, Y2, X, R, V)

●266MHZ-verwerker, geheuekapasiteit van 64M

● Matrysbiblioteek, 30 boonste matryse, 30 onderste matryse

● USB-geheue-koppelvlak, RS232-koppelvlak

● Mikroskakelpaneel, databewerking

● Bereken outomaties die buigdruk en

die veiligheidsgebied

DA58T

● 2D grafiese raakskermprogrammering

●15 hoë-resolusie kleur TFT

● Berekening van buigvolgorde, kroningsbeheer

●Servo- en frekwensie-omskakelaar

● Gevorderde Y-as beheer algoritmes vir

geslote lus sowel as oop lus

kleppe. USB, perifere koppelvlak

DA66T

●2D-aanraakgrafika-programmering, 3D-produk

figuur analoog vertoon,

●17 hoë resolusie

TFT-kleurskerm

●◆Volledige Windows-toepassingspakket

● Versoenbaar met DELEM modulêre struktuur

● USB-randapparatuurkoppelvlak

● Hoekopsporende sensorkoppelvlak

Tegniese Spesifikasies

| Model | Buigdruk (Kn) | Buiging Lengte (mm) | Afstand van die distrik (mm) | Keeldiepte (mm) | Skuifbalkslag (mm) | Maks Opening Hoogte (mm) | Y1, Y2-as afwaartse spoed (nw/sek) | Y1,Y2-axk Terugslagspoed (mm/sek) | Y1, Y2-asse Presisie (mm) | X-ais Maks. Afstand (mm) |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 150 | 150 | 0.01 | 500 |

| 100T/3200 | 1000 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 125T/3200 | 1250 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 300T/3200 | 3000 | 3200 | 2700 | 400 | 200 | 420 | 150 | 150 | 0.01 | 500 |

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 150 | 150 | 0.01 | 500 |

| 500T/6000 | 5000 | 6000 | 4900 | 500 | 320 | 600 | 150 | 150 | 0.01 | 800 |

| 600T/6000 | 6000 | 6000 | 4900 | 500 | 320 | 600 | 150 | 150 | 0.01 | 800 |

| 800T/6000 | 8000 | 6000 | 4900 | 600 | 400 | 600 | 150 | 150 | 0.01 | 800 |

| 800T/8000 | 8000 | 8000 | 5900 | 600 | 400 | 600 | 150 | 150 | 0.01 | 800 |

| 1000T/6000 | 10000 | 6000 | 4900 | 600 | 400 | 600 | 150 | 150 | 0.01 | 800 |

| 1000T/8000 | 10000 | 8000 | 6900 | 600 | 400 | 600 | 150 | 150 | 0.01 | 800 |

| 1W0T/10000 | 10000 | 10000 | 8000 | 600 | 400 | 600 | 150 | 150 | 0.01 | 800 |

| Model | Werkstuk Lineêre Graad | Agter Meter Presiswn | Gly Voorkant Ondersteunende arms (stkS) | Sleg Stop (stkS) | V-as Kroning | CNC Beheer Aies | Hoofmotor W | Lengte*Breedte*Hoogte (mm) | Gewig |

| 63T/2500 | ≥0.3mm/m | 0.05mm | 2 | 2 | Hidrouliese | Y1+Y2+X+V | 5.5 | 3100*1450*2050 | 5.8 |

| 100T/3200 | ≥0.3mm/m | 0.05mm | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 7.5 | 3500*1580*2400 | 8.5 |

| 125T/3200 | ≥0.3mm/m | 0.05mm | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 11 | 3500*1580*2400 | 9.5 |

| 160T/200 | ≥0.3mm/m | 0.05mm | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 11 | 3500*1650*2500 | 11 |

| 200T/3200 | ≥0.3mm/m | 0.05mm | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 15 | 3500*1680*2550 | 14 |

| 250T/3200 | ≥0.3mm/m | 0.05mm | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 15 | 3500*1700*2600 | 15.5 |

| 300T/3200 | ≥0.3mm/m | 0.05 nini | 2 | 3 | Hidrouliese | Y1+Y2+X+V | 22 | 3500*1800*2730 | 16.8 |

| 400T/4000 | ≥0.3mm/m | 0.05mm | 2 | 4 | Meganies | Y1+Y2+X+V | 30 | 4000*2450*3500 | 31 |

| 500T/6000 | ≥0.3mm/m | 0.05mm | 2 | 6 | Meganies | Y1+Y2+X+V | 37 | 6500*2810*4500 | 53 |

| 600T/6000 | ≥0.3mm/m | 0,05mm | 2 | 6 | Meganies | Y1+Y2+X+V | 45 | 6500*2910*5100 | 68 |

| 800T/6000 | ≥0.3mm/m | 0.05nm | 2 | 6 | Meganies | Y1+Y2+X+V | 55 | 6500*2950*5300 | 90 |

| 800T/8000 | ≥0.3mm/m | 0.05mm | 2 | 8 | Meganies | Y1+Y2+X+V | 55 | 8500*2950*5900 | 120 |

| 1000T/6000 | ≥0.3mm/m | 0.05mm | 2 | 6 | Meganies | Y1+Y2+X+V | 2*37 | 6500*3000*5600 | 100 |

| 1000T/8000 | ≥0.3mm/m | 0.05mm | 2 | 8 | Meganies | Y1+Y2+X+V | 2*37 | 8500*3000*6100 | 130 |

| 1000T/10000 | ≥0.3mm/m | 0.05mm | 2 | 10 | Meganies | Y1+Y2+X+V | 2*37 | 10500*3000*5850 | 150 |